Exhaust Gas Recirculation

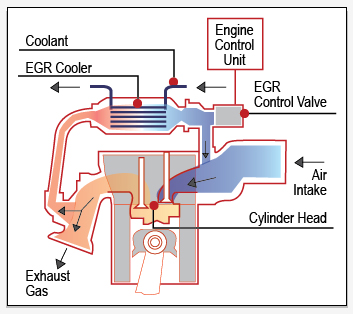

A widely adopted route to minimize NOx emissions is Exhaust Gas Recirculation (EGR). This entails recirculating a controllable proportion of the engine’s exhaust lower back into the consumption air. A valve is typically used to control the waft of gas, and the valve can also be closed absolutely if required.

The substitution of burnt fuel (which takes no further phase in combustion) for oxygen prosperous air reduces the percentage of the cylinder contents available for discharge. This motivates a correspondingly decrease in heat release and maximum cylinder temperature and reduces the formation of NOx. Inert gas in the cylinder further limits the height temperature (more than throttling alone in a spark-ignition engine).

The gasoline to be recirculated may also be passed via an EGR cooler, common in the air/water type. This reduces the temperature of the gas, which reduces the cylinder charge temperature when EGR is employed. This has two benefits- the reduction of cost temperature consequences in decrease height temperature. The larger density of cooled EGR gasoline allows a more significant share of EGR to be seethe recirculated fraction may also be as excessive a diesel engine ve as 50% under some operating conditions.

Exhaust Gas Recirculation Solution

Here at Quantum Tuning have a very advanced answer for EGR valves can end up clogged with carbon deposits, inflicting them to fail or stick, leading to error codes and low running. We have developed a sophisticated solution to disable EGR, a high-quality and straightforward method of enhancing your engine’s efficiency.

Our EGR closed or blanking solution and reprogramming of the engine management ECU results in lowered engine temperatures, improved throttle response and economy, and lengthen engine life by reducing oil contamination and carbon deposits.

Exhaust Gas Recirculation Benefits

Modern engines recirculate some of their exhaust gases lower back into the machine to lower emissions. This is the significant gain of the EGR system. The drawback is that exhaust fumes containing carbon deposits are continuously being recirculated via the engine through time, causing a build-up of carbon deposits in the consumption manifold.

These deposits now and again contribute to the failure of the EGR machine itself. Replacement EGR valves can be steeply-priced, and in the case of high mileage engines, the continual carbon construct up can ultimately lead to total engine failure.

Removal of the EGR machine using blanking off the exhaust input and reprogramming of the ECU results in decreased engine temperatures, elevated throttle response and economy. It can lengthen engine existence using lowering oil illness and carbon deposits.

Exhaust Gas Recirculation Works

The (EGR) Exhaust Gas Recirculation works by sending a small phase of inactive fuel exhaust lower back into a vehicle’s cylinders, hence eject negligible toxins into the environment. This reduces the combustion heat, but the identical quantity of stress is still applied to this piston while decreasing excess oxygen quantity before combustion. A few research on diesel engines exhibit that the element of nitrous oxide gasoline emissions is indeed reduced through EGR; however, concentrations of smoke density can genuinely increase. Thus there seem to be pluses and minuses depending on what’s important to you in your unique vehicle.

Usually, an engine recirculates exhaust fuel via piping it from the exhaust manifold to the inlet manifold. This sketch is referred to as exterior EGR. A control valve (EGR Valve) inside the circuit regulates and times the gasoline flow. Some engines contain a camshaft with a positively giant overlap. Each the intake valve and the exhaust valve are open, thus trapping exhaust fuel inside the cylinder by not entirely expelling it during the exhaust stroke. Quantum Tuning has a database of over 50,000 individual files supplying a network of approximately 1000 dealers the world over – we are the largest ECU Remapping and Chip Tuning dealer group.